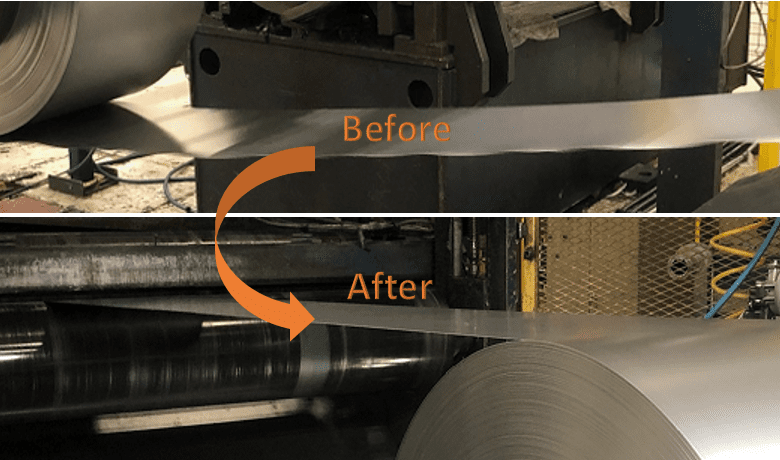

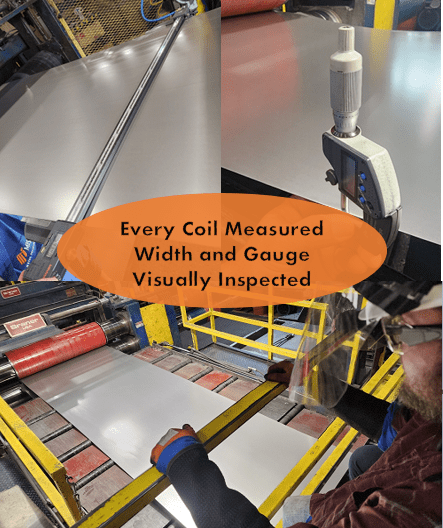

We have five slitting lines in three states covering the Southeast. We can slit gauge ranges from 0.457mm to 9.0mm. We can maintain 0.013mm tolerances and slit widths down to 30mm. We slit a variety of materials including HRPO, CR, Galvanized, Pre-Paint, Motor Lam, Stainless and Aluminum.

We also do toll processing of Carbon Steel (HRPO, CR, GA, GV, Painted, Coated, EG),, Stainless, and Aluminum for thicknesses from 0.010″ (0.254mm) to 0.091″ (2.3mm) in widths from 1” (25.4mm) to 72” (1,829mm).